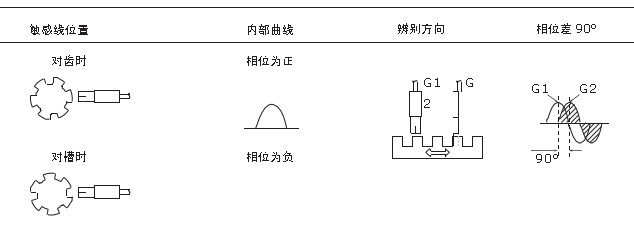

The core component of Kejit gear speed sensor uses magnetoresistance as the detection component, and then uses a new signal processing circuit to reduce noise and improve functions. By comparing with the output waveforms of other types of tooth speed sensors, the error of the measured speed is extremely small and the linear characteristics are very consistent. The sensing objects are magnetic materials or magnetically permeable materials, such as magnetic steel, iron and electrical steel. When the magnetic or permeable material with protrusions (or depressions) on the measured object rotates as the measured object, the sensor outputs a pulse signal related to the rotation frequency to achieve the purpose of speed measurement or displacement detection.

| Sensing Distance | 2-3mm |

| Output | NPN/PNP Automatic Identification |

| Output current | 50mA |

| Operating voltage | 12-30VDC |

| sensing precision | ±one pulse |

| curreny consumption | ≤15mA |

| response frequency | 0Hz~33KHz |

| Applicable module | tooth spacing≥3mm |

| ambient temperature | - 2 5℃~ 7 0℃ |

◇Because there is a permanent magnet inside the sensor, care should be taken during installation to avoid collision between the gear and the sensor head due to attraction, which may cause damage to the sensor.

◇If the surrounding electromagnetic interference is large, it is recommended to add a shielded wire, that is, the shell is grounded.

●35mm standard guide rail installation method;

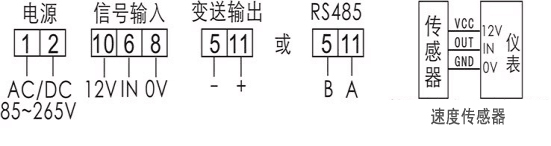

●Input signal: Hall switch, proximity switch, photoelectric switch, encoder, etc.

●The transmitter outputs DC12V to power the sensor, and no additional sensor power supply is required;

●Output DC4-20mA, 0-20mA, 0-5V, etc. The rotational speed value is proportional to the output signal. The corresponding relationship between the rotational speed value and the output signal is set according to user requirements before leaving the factory. For example: set 0-3000rpm to correspond to 4-20mA. When the user measures the transmission output signal to be 8mA, the corresponding rotation speed is 750rpm.

●RS485 interface output, using standard modbus-rtu protocol, can be networked with PLC, touch screen, configuration software, etc. The instrument address, communication baud rate, and parity bit can be set according to user requirements before leaving the factory. After leaving the factory, users can use our host computer software to set them themselves.

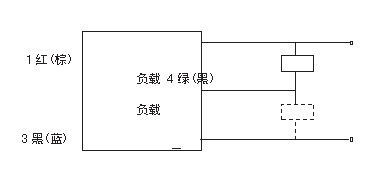

Diagram

Nanjing KJT Electric Co,.LTD

Nanjing KJT Electric Co,.LTD