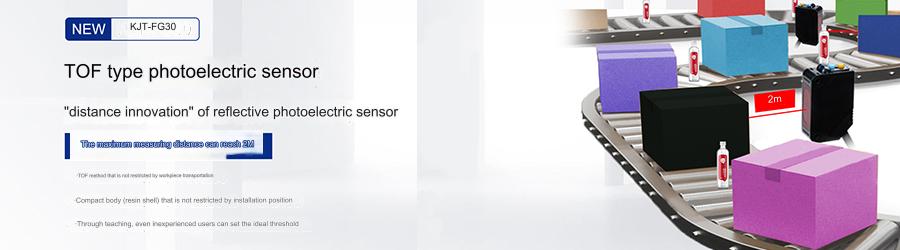

In the past, traditional reflective photoelectric sensors had problems such as "short detection distance", "erroneous detection due to the color of the workpiece", and "large sensor body", and had certain limitations in use. The TOF detection principle is adopted to fundamentally change the problem that optoelectronic products are easily affected by target objects.

| Laser light source |

Laser diode 650nm, ≤1mW; compliant GB7247.1-2001, Class I laser eye safety requirements |

| Laser level | Class 1 |

| Ranging frequency | 1000Hz Adjustable |

| working distance | 0.05m-2m |

| 10% reflectivity | 1m |

| Response time | lms (adjustable) |

| system error | ±10mm |

| persistent error | ±3mm |

| Operating Voltage | 9-36V |

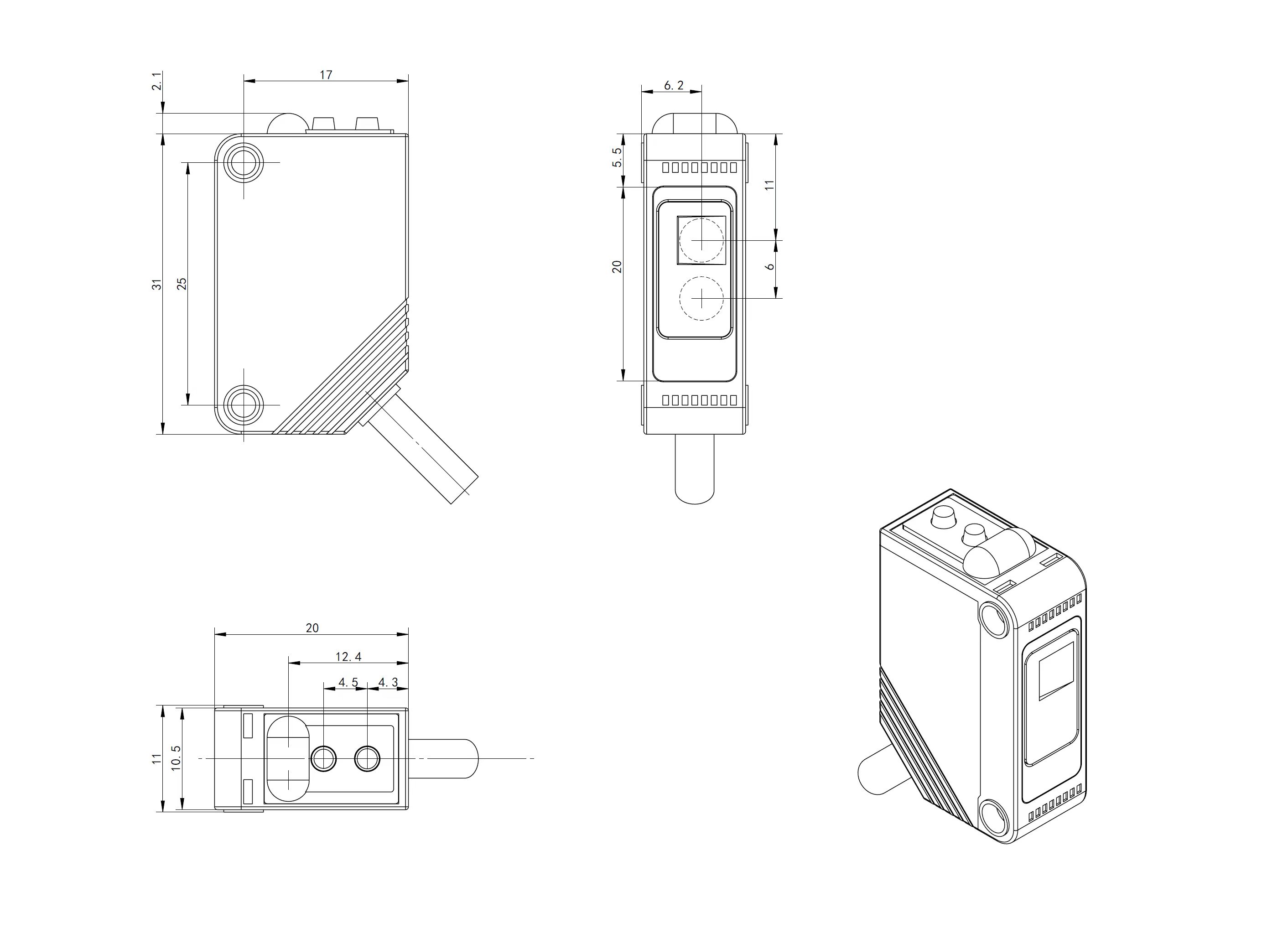

| interface | PNP/NPN/TTL serial port |

| Power consumption | 0.5W |

| weight | <10g |

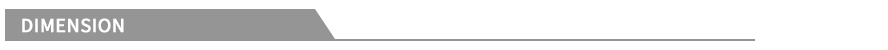

| Dimensions (length, width and height) | 33mn x20mm xl1mm |

| Protection level | IP65 |

| Working temperature | -20C-+75℃ |

| Storage environment temperature | -40C-+100℃ |

| Ambient light resistance | >50klux |

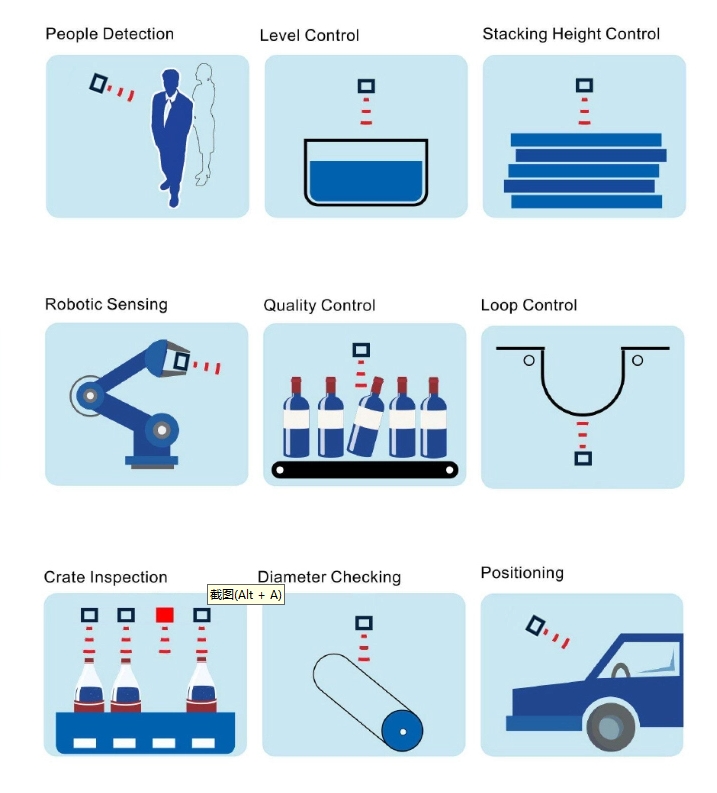

Compared with traditional photoelectric switches that rely on light quantity feedback to detect objects, the KJT-FG30 photoelectric sensor using TOF technology has the following advantages:

1: More accurate positioning

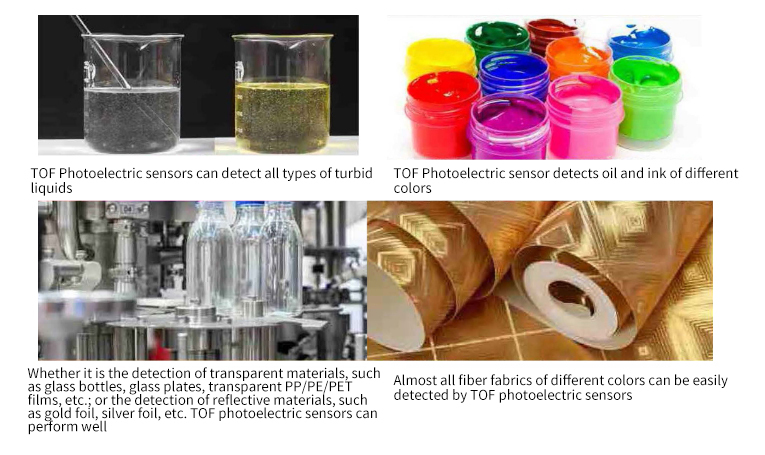

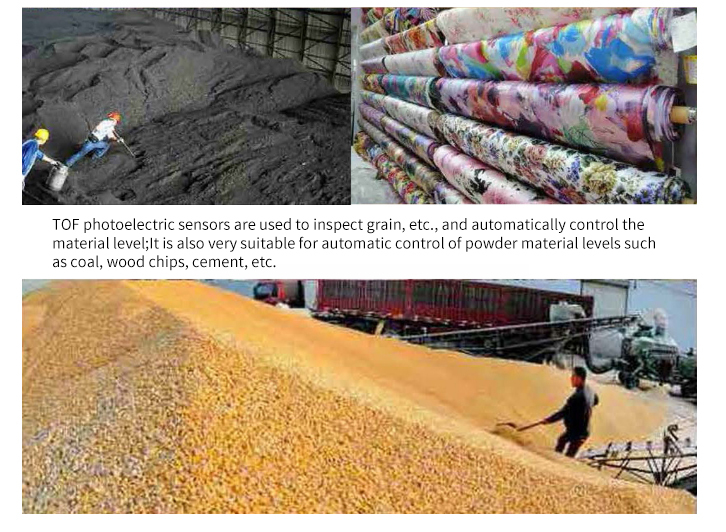

2: Reduce the interference caused by the color, curvature, environment, etc. of the object surface

3: Switching frequency up to 1000 Hz

4: Can detect transparent objects stably.

5: Not affected by sunlight, can be used outdoors.

6: Achieve longer detection distance (diffuse reflection can reach up to 4 m! It is the only laser photoelectric sensor on the market)

7: The convenient and easy-to-use operation method allows ordinary models to quickly set two switch points.

Nanjing KJT Electric Co,.LTD

Nanjing KJT Electric Co,.LTD