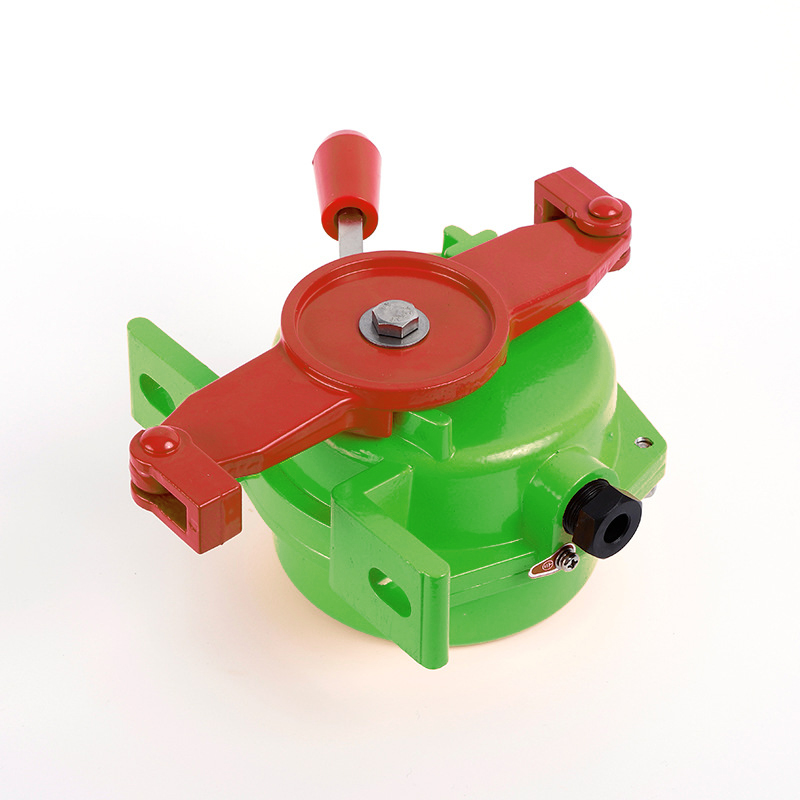

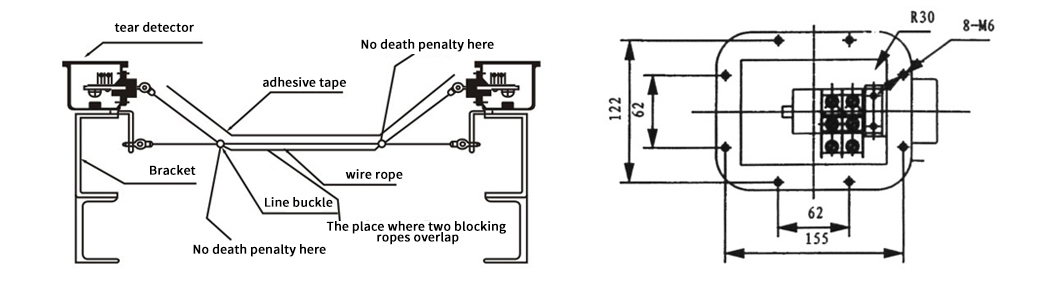

KJT-SL type vertical and longitudinal tear detector is designed to provide reliable protection for expensive belt mixes. The detector can be carried out in the eye. When the belt is torn or broken, or important or sharp objects scratch the belt, the tear detector can provide an alarm signal to the monitoring personnel or shut down the conveyor. Tear detectors are installed in pairs on both sides of the conveyor belt. They are connected by two sections of steel wire ropes (the steel wire ropes are covered with plastic jackets). One end is permanently fixed on the support bracket to prevent the rope from being lost, and the other end is connected to the elastic ball of the tear switch. The upper two sections of steel wire rope form a closed loop under the belt. When an object or torn belt rope is hung down and swept down to one or two steel wires, the elastic ball is pulled out of the base, and the tear switch sends out an alarm signal or a shutdown signal. . After the accident is dealt with, reinstall the spring ball into the base and tear the switch to eliminate the alarm signal. Simple and effective, it provides reliable and stable alarm and shutdown protection for possible damage to the conveyor belt. Although the detector has a simple principle, it plays a very important role. The solid shell, heavy-duty structure and simple installation method make the detection The device works in any harsh environment.

![]()

| Ambient temperature | -30℃~+50℃ |

| Relative humidity | NO LESS THAN 85% |

| Maximum stroke | 10mm |

| Action force | 70-100N |

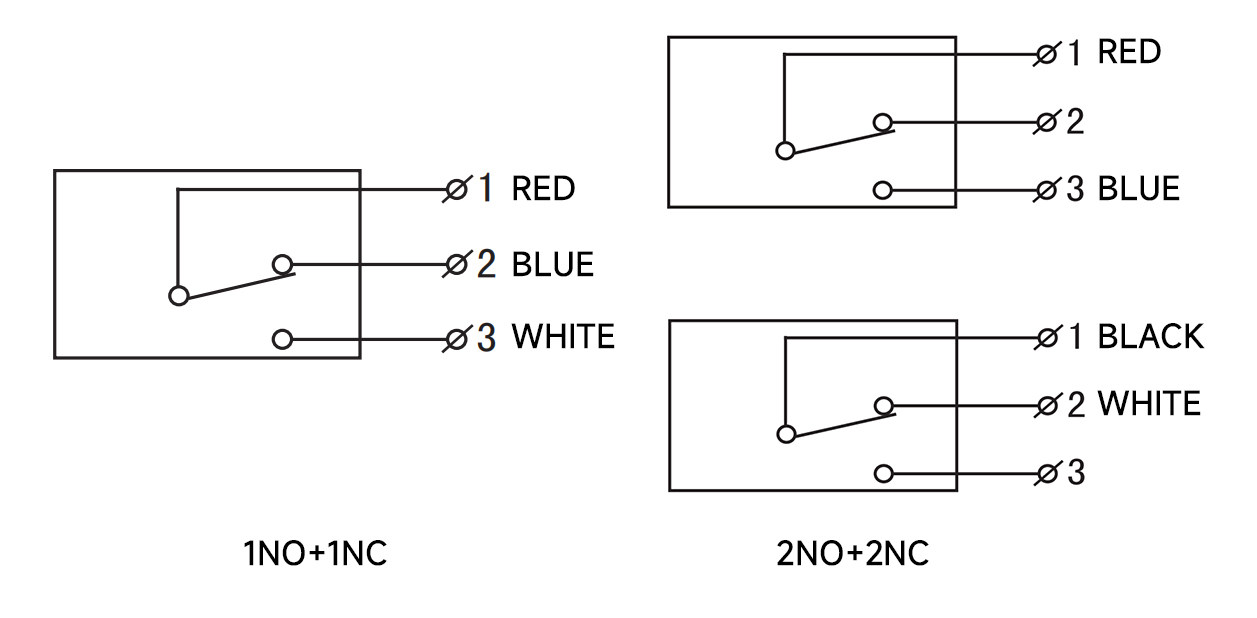

| Number of contacts | 2NO,2NC |

| Contact rating | AC380V/5A |

| Reset mode | Manual |

| Reliability | >100,000 times |

| Protection level | IP65/IP67 |

| Weight | 5Kg |

![]()

![]()

![]()

Nanjing KJT Electric Co,.LTD

Nanjing KJT Electric Co,.LTD