KJT-LSM-II type Ramsay type two-way balanced pull rope switch series is widely used in factories and mines with belt conveyors such as steel, cement, power plants, mines, etc. This product is installed on both sides of the belt conveyor and is used A protective switch used to shut down the belt conveyor in an emergency. Pull the wire rope at any point within the operating distance of the switch to cut off the operating circuit and shut down the entire line, thus protecting the safety of the belt conveyor and people.

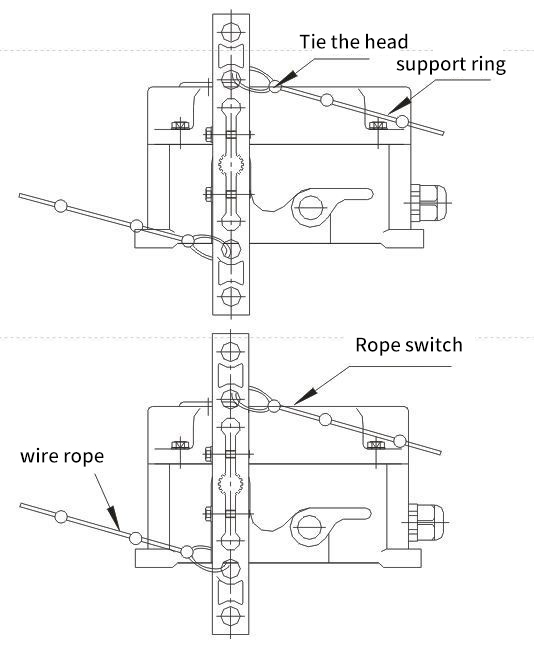

working principle:

When an emergency occurs at the tape transportation site, pulling the wire rope tied to the lifting eye is the action of the slider and switch in the machine, which sends a shutdown signal. The switch is manually reset after releasing the wire rope.

![]()

| Ambient temperature | -40℃~50℃ |

| Relative humidity | 0~95% |

| Action angle | 20°-30° |

| Extreme angle | 75° |

| Action force | 70-100N |

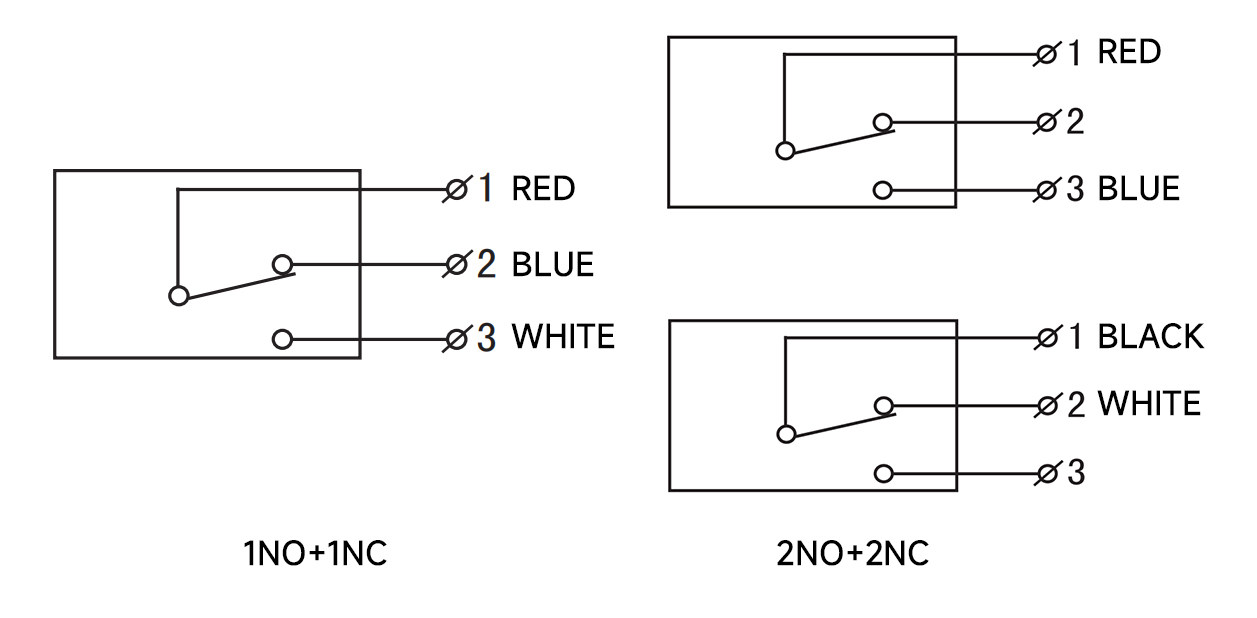

| Number of contacts | 1 NO, 1 NC (2 groups of NO and 2 groups of NC can be added as needed) |

| Contact rating | AC380V 5A DC24V 5A |

| Reset mode | Manual / Auto |

| Electrical life | >100,000 times |

| Protection level | IP65/IP67 |

| Weight | 3.5Kg |

![]()

![]()

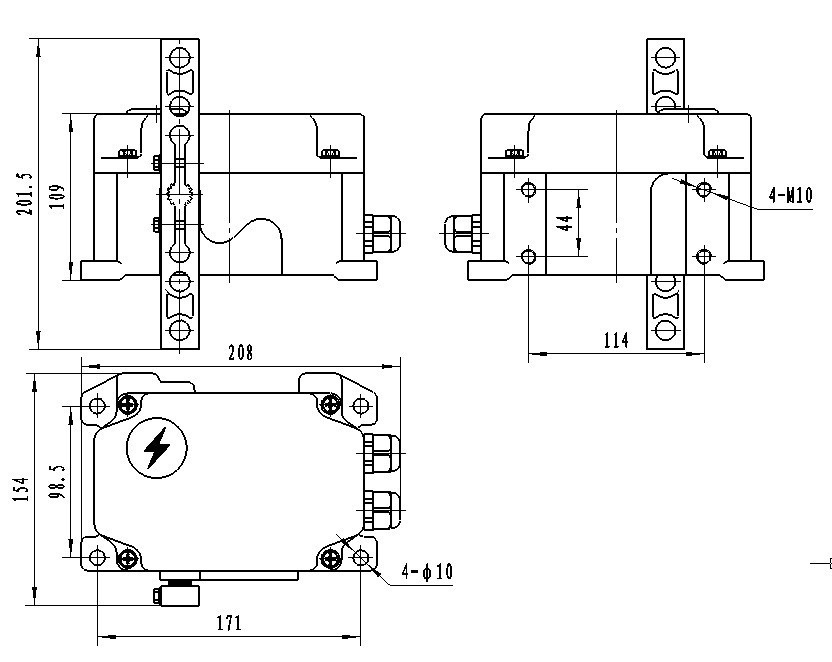

●The switch must be balanced and pressed on the fixed bracket of the rack;

●Tie the steel wire rope to the pull rings at both ends, and the rope on each side should not exceed 40m (it should be shortened when there is a slope);

●The pressure on the pull rope should be appropriate to ensure reliable reset of the switch;

●The drawstring is set parallel to the tape, and a lifting ring is added every 10m.

●The factory can purchase steel wire ropes according to the specifications required by users.

The address encoder uses a self-designed protocol to provide an RS485 communication interface to connect to the comprehensive protection instrument. By using shielded twisted pairs and communication repeaters, the transmission distance can reach 1km.

![]()

Nanjing KJT Electric Co,.LTD

Nanjing KJT Electric Co,.LTD