KJT-LK-II roller material flow detector is used to detect the materials transported by the belt conveyor and can send out a loaded operation

signal.If connected with a sprinkler device, the automatic sprinkler function for logistics can be realized. This device is also suitable for

bi-directional tape conveyors.

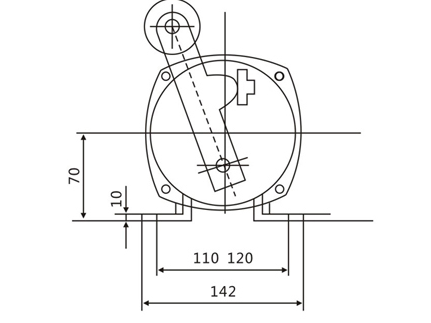

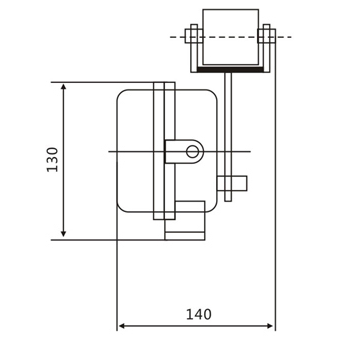

The detector adopts load-type detection. After the running tape is loaded, the tape sinks. The detection wheel installed under the tape is

pressed and drives the internal limit switch through lever transmission to output a switch signal to realize the detection function.

![]()

![]()

![]()

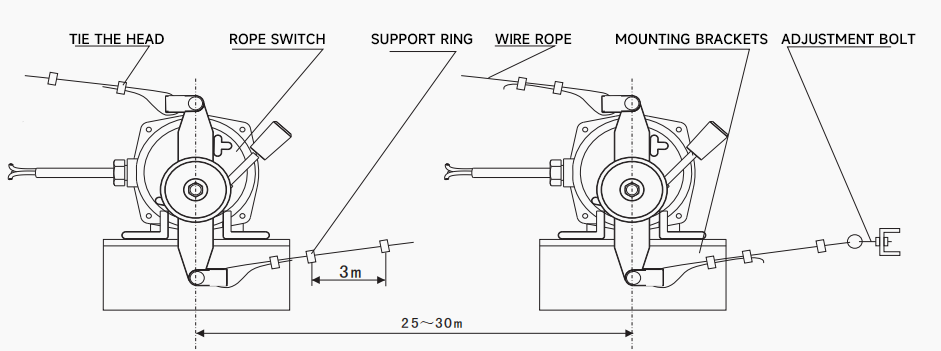

●The switch must be balanced and pressed on the fixed bracket of the rack;

●Tie the steel wire rope to the pull rings at both ends, and the rope on each side should not exceed 40m (it should be shortened when there is a slope);

●The pressure on the pull rope should be appropriate to ensure reliable reset of the switch;

●The drawstring is set parallel to the tape, and a lifting ring is added every 10m.

●The factory can purchase steel wire ropes according to the specifications required by users.

The address encoder uses a self-designed protocol to provide an RS485 communication interface to connect to the comprehensive protection instrument. By using shielded twisted pairs and communication repeaters, the transmission distance can reach 1km.

| GROUP | TERMINAL | WIRING INSTRUCTIONS |

| AC 220V | L |

L/N IS CONNECTED TO AC 220V POWER SUPPLY TO POWER THE ADDRESS ENCODER.L AND N ARE RESPECTIVELY EQUIPPED WITH TWO INPUT INTERFACESBOTH OF WHICH CAN BE USED. |

| N | ||

| INPUT 2 HARDCONTACT | COM2 | HARD CONTACT COMMON TERMINAL |

| NC2 | HARD CONTACT NORMALLY CLOSED POINT | |

| NO2 | HARD CONTACT NORMALLY OPEN POINT | |

| RS485 | A |

A&B ARE RESPECTIVELY CONNECTED TO RS485 SIGNAL LINES AND CONNECTED TO A&B ON THE COMPREHENSIVE INSUR- ANCE INSTRUMENT THROUGH THE COMMUNICATION BUS. |

| B |

![]()

Nanjing KJT Electric Co,.LTD

Nanjing KJT Electric Co,.LTD